Explore the evolution of VR controller holders, from early designs to cutting-edge technology and future trends in VR interaction.

Explore the evolution of VR controller holders, from early designs to cutting-edge technology and future trends in VR interaction.

Explore the fusion of tradition and tech in appliance design, from Bauhaus influence to retro revival, blending history with modern innovation.

Discover how understanding the structure of the hand can influence design decisions, ensuring optimal user comfort and functionality.

What’s involved when designing products for the premium market? Find out more here, as we detail the 11 essences of premium design.

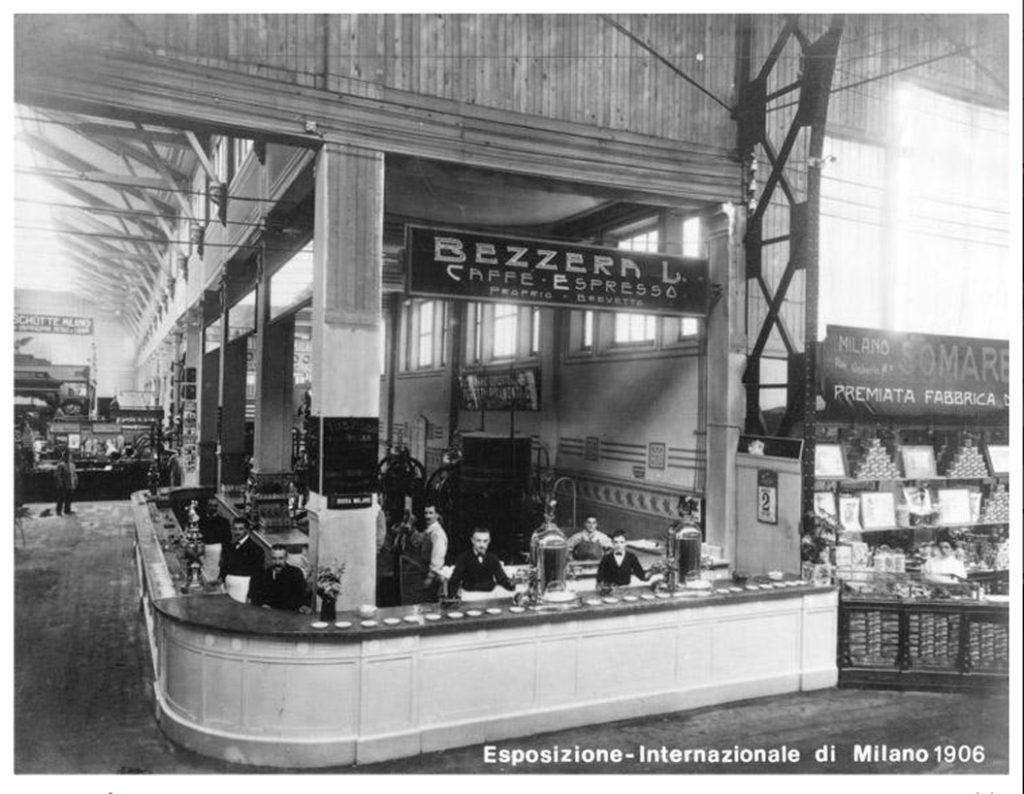

Discover the evolution of espresso machines from early innovations to modern home and commercial uses, shaping coffee culture.

Virtual Reality (VR) is more than just an immersive experience; it’s a leap into a…

The traditional kitchen is undergoing a radical transformation. The advent of modular appliance design marks a significant shift in how we perceive and interact with our culinary spaces.

In the quest for a greener home, the kitchen represents a pivotal battleground. It’s where…

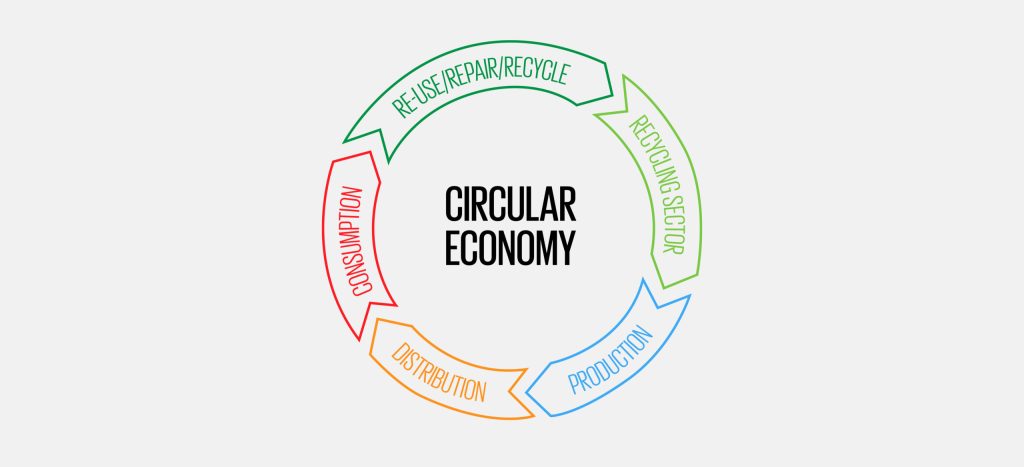

Circular economy provides the roadmap for a more sustainable future. Read why your product should incorporate EOL strategies.

Unlock success with this deep dive into the hidden challenges of product design. Learn to embrace failures and turn them into triumphs.